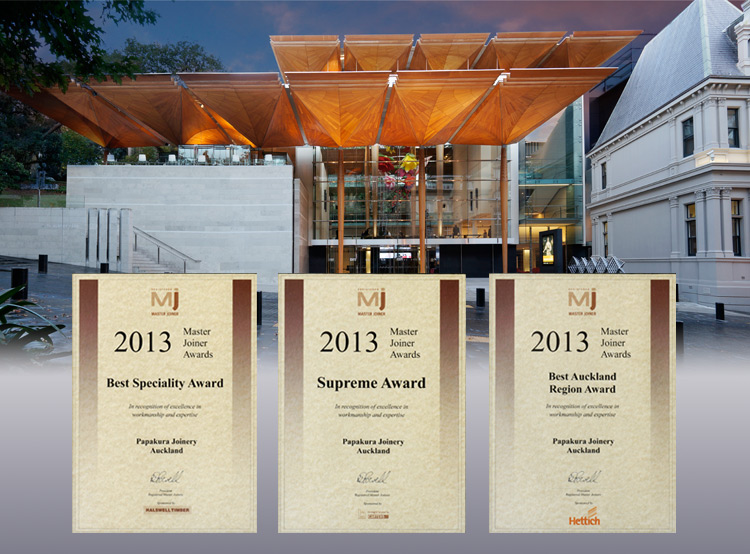

Auckland Art Gallery Project

In 2013 Papakura Joinery recieved three Master Joiner Awards for it's work on the Auckland Art Gallery Project, Best Speciality Award, Best Regional Award, and New Zealand Supreme Award. The project also recieved three commendations.

The building has won numerous awards including World Building of the Year.

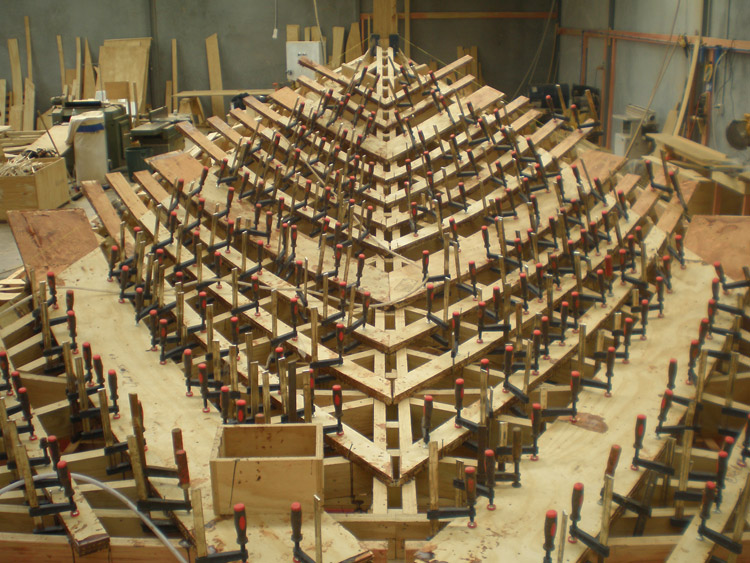

The project comprised the construction of 22 canopy sections, six half sections and 23 kauri columns (up to 15m high) to be installed as a massive roof structure.

Tolerances for the project were extremely fine, not more than 0.2mm on the interlocking corners and overall for each 10-12m x 5m canopy, 1mm.

All kauri was from fallen stock so no new trees were felled for the project. With strict stipulations on colour and grain, continuity of supply was particularly challenging. In the original design the panelling was to be butt-fitted, but during trials this was modified so that there would be a small gap between panels, emphasising the design. The panels were glued and back screwed to the sub-structure.

more...

Each canopy had to be built so that it could be broken down into 8 parts for storage and transport. Some of the canopies had compound curves that so tight steam bending was used to shape the kauri.

In addition to the canopies, kauri covers were constructed for the project's columns and giant laminated louvre blades for the front of the canopies.

THE BRIEF

To create a sympathetic new structure to complement the adjacent existing heritage building.

To be recognised internationally as a model of unparalled excellence.

To blend with the local environment - a tree clad park.

Extensive use of glass to provide views through to the park and highlight the scale of the newly created spaces.

To use a timber species iconic to New Zealand.

To provide opportunities to participating contractors to showcase their abilities and advance their craft.

CHALLENGES

A complex, 3 year project with no historic comparison for pricing & manufacture.

Required the establishment of a 1,000m2 manufacturing and storage base for the project with CNC, steam bending, laminating and all fabrication and finishing equipment. Twenty extra employees including carpenters, joiners, cabinet makers, boat builders and labourers were required at the peak of production.

All the canopies had to be built prior to any being installed to meet strict contractual demands on delivery. Each canopy had to be disassembled into 8 sections for storage and later transport and installation on site.

Continuity of Kauri supply was particularly challenging given the narrow specified parameters governing grain and colour match. 250m3 of Kauri were used on the project.

CAD drawings were supplied for all components of the project but when problems arose with consistency of the curves on different size pods responsibility passed to the contractor. Traditional methods including string lines were used to create accurate cross sections.